My parents used often the expression,

“You can’t make a silk purse out of a sow’s ear”. When it comes to art for specialty foils for

the LT5C, this expression is especially true.

You may find this post about using

various unique materials and white with the LT5C of interest.

If you have requirements to print

foils, Kraft or other unique materials, the LT5C is your best option. Let me tell you more about a recent request

from a company with this requirement.

|

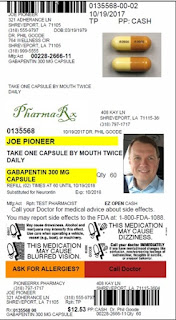

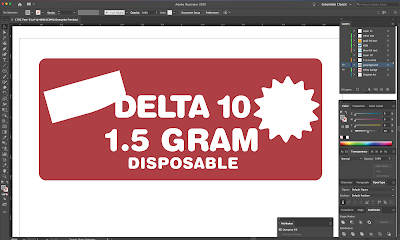

| Original Foil Print File |

To start this process, a company sent

us the pdf file above to print. As I

understand, they send this art to a third-party printer currently; however,

they need to move this production in-house given all their SKU’s.

|

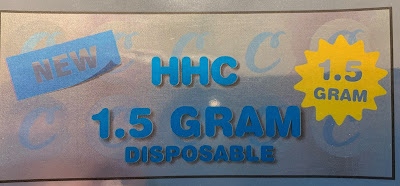

| Preprinted Foil Labels |

Reviewing their preprinted labels, we

noticed a light grey, matte finish, background with blue and gold foils. Given

the customer’s requirements for spot foil colors, we needed to find a way to replicate

this look on a light grey background.

Although I’m not a pressman, I think

the printer used some type of analog press plus foil stamping to achieve both

blue and gold foils on the same label. Perhaps they used one of those very

expensive presses, but for sure, the printer was not an “on-demand option”.

|

| Original Art-LT5C Printed Without White |

To start the process, Tony Molina,

Graphic Artist for Color Label Solutions, thought the best way to replicate the

preprinted label was to use a neutral, high gloss, silver foil. The Afinia LT5C has the ability to print on

all sorts of different media, especially foil media. Tony printed the PDF art

file supplied by the customer without any of the white print options available

on the LT5C. But the result was not very

good. According to Tony, “the high gloss silver foil color showed through the

entire label; making the colors somewhat dull or washed out. Everything was

shiny and reflective. The words “NEW”

and “1.5 GRAM” came out silver and not white as they appeared in the pdf file. Not what the customer wanted.”

|

| Original Art-Printed With White |

One of the options you have on the

LT5C is to add white to the background of the entire label. Using this option,

all the colors appeared matte and dull.

Again, not what was desired by the customer.

So, in Tony’s opinion, “To get a nice

blue and gold foil effect, he needed to redesign the art in a way that takes

advantage of the high gloss, silver foil media background as well the white

printing capability of the LT5C. Using

Adobe Illustrator, I was able to accomplish the desired results.”

Here is a summary of how Tony built the

art file in Illustrator and used the capabilities of the Afinia LT5C

4-COLOR+White Label printer to achieve the requirements of our customer.

|

| White Layer |

First Tony created a layer and

assigned the “SpotColor_White” background element covering the entire label

except where the foil colors were desired.

Tony chose a “Peach” color as shown on the palette figure below.

|

| White Layer |

Next he created another layer, copied

the same background white element and pasted it in place, and assigned a light

gray color to it. He set the light gray color to overprint the white.

|

| White and Grey Layers |

The white with the grey layer on top,

moved slightly to show both layers.

|

| White And Grey Layers |

The grey on top of the white layer (Peach

Color) shows up as a darker red in the Illustrator file.

|

| Background Layers With Elements |

With the background layers finished,

Tony added the other design elements without any background. This method enables Tony to “TRAP” the blue

and yellow colors to the background.

|

| "Trapped" Colors |

Using this method, the blue and yellow

colors will print directly onto the high gloss silver, producing the desired blue

and gold foil effects required by the customer.

|

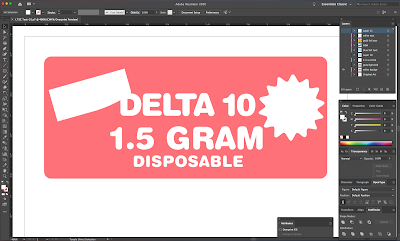

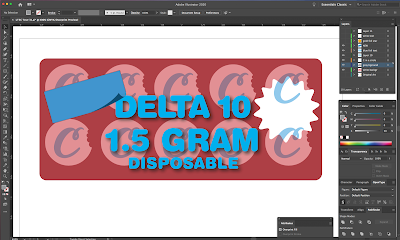

| Final White Text |

With the background and other elements

completed, Tony added the final White text (NEW & 1.5 GRAM) indicated in the Peach Color. In the top right of the picture above, you can

see the list of layers Tony used to recreate the art necessary to print the

desired output on the LT5C.

By using a solid, opaque, light

gray background with white under print, he created the contrast allowing the

blue and yellow colors to become “blue foil” and “gold foil”.

|

| Final Foil Print Output |

Once the art was completed, Tony saved

the Illustrator file as a PDF X1-a Standard pdf file. Then, he configured the LT5C Postcript driver to

print with the option “APPLICATION SPECIFIC”; meaning the designated white

color elements will print behind a particular color to make the colors pop. Plus, the white color can be used as an

element as part of the overall label design.

To help graphic artists design with

white, Afinia has released a design suggestion on using white. I encourage you

to review this information before creating or using the LT5C to print any files with

white.

Once the “ART FILE” was configured

correctly, Tony was able to achieve the desired finished label using the LT5C with

high gloss silver foil media.

|

| Blue/Yellow Foils Upclose |

Tony says, “After being able to

understand how “WHITE” in your design really works, the LT5C was able to

represent very closely the print made from an expensive label press using most

probably specific PMS inks. The fact

that we can replicate this print output using a digital printer with a silver

foil label is impressive; especially given the requirement for a foil look

for cyan and gold/yellow.”

With a knowledgeable graphic artist,

silver foil and the LT5C, you can create great looking, color foil labels. If you want to use various color foil labels

on your products, contact us. We’ll help

you get started printing high quality labels yourself.

Guy Mikel

855-962-7670